Posted by Pam Hoddinott

Posted by Pam Hoddinott Nearly 6 million commercial buildings in the U.S. were built prior to 1980, which was before many of today’s energy efficiency products, equipment standards, and building codes existed. According to the Office of Energy Efficiency & Renewable Energy, “These buildings represent a significant opportunity to unlock energy savings through efficiency improvements…”.

When the subject of energy efficiency comes up, there are so many different buzzwords out there today. We hear the term ESG which is short for environmental, social, and governance. We also hear the terms sustainability, decarbonization, energy systems solutions, and how building operators are trying to achieve net zero by a goal date of 2025, 2030, 2040, or whatever it might be. The term “Net Zero” is a goal-setting phrase that a large portion of Fortune 500 CEOs include in their annual reports. All that being said, this nomenclature focuses on a straightforward concept of making existing buildings more efficient operationally, reducing maintenance costs, and lowering CO2 output. These are all the things that go into operating brick-and-mortar buildings more efficiently.

One of the simplest forms of energy efficiency is a lighting retrofit. Simply put, it’s refitting existing light fixtures with modern technology, such as LED lights. In the last ten years, LED has become quite popular and affordable. You hear it in reference to everything – from our homes to the workplace, whether it is industrial manufacturing, healthcare, warehousing distribution, commercial office space, and schools. Every type of facility that is a brick-and-mortar building has lighting.

It’s incredible to me that the simplest concept of upgrading a lighting system that can generate an ROI from 20 to 50% isn’t top of mind for more people. You certainly can’t get that ROI in the stock market. Energy-efficient solutions such as lighting programs are sometimes overlooked, and when clients have a large portfolio of buildings – like a retail chain that might have 1800 stores – basic blocking and tackling suggests that we would look at lighting first, but more time than not, it gets put on the back burner.

So, why does it make sense to switch to LED technology? The obvious reason for doing a national lighting retrofit project is energy savings. The potential ROI for lighting projects is somewhere between 20 and 50%. Don’t think of it as spending money on lighting projects; instead, think about it as an investment.

Aside from energy savings, there are many other reasons to replace or retrofit your lighting systems with new LED technology. There are also compelling savings on maintenance due to the longer lifespan of LED, which can be upwards of five times that of traditional fluorescent or incandescent light sources.

The improved quality of light for employees, faculty, or customers is tremendous based on the improved color rendering with LED. Not to be overlooked is the safety aspect of energy efficiency consulting services such as a lighting retrofit. Safety can be boosted, whether it is inside a factory or outside in a parking lot. Also, LED lighting is a very controllable light source which drives additional savings in the long run. LEDs can operate at less than full power providing additional efficiencies as the power is reduced.

Greenhouse gas emissions reduction in metric tons of CO2 can be quite substantial and will certainly be very helpful as a part of a more comprehensive sustainability or ESG program.

Last, lighting retrofits can be paid for with existing operating funds Opex rather than Capex or capital funds. Implementing energy savings opportunities that optimize energy use allows you to take those savings and reinvest them back into your organization. Essentially, you now have a new funding source, and we call Making Energy an Asset®.

Let’s dive a little deeper into the financing of a national LED lighting program. There are many different financing vehicles available – operating leases, capital leases, or energy efficiency as a service (EEaaS), which is the newest form of lease structure for lighting and other energy-efficient solutions. Energy efficiency as a service is a different form of a lease with no buyout at the end of the term, which allows for potential off-balance sheet treatments keeping debt off the books.

We’ve covered several compelling reasons why a national lighting retrofit program should be one of the first steps in an organization’s energy efficiency or ESG program.

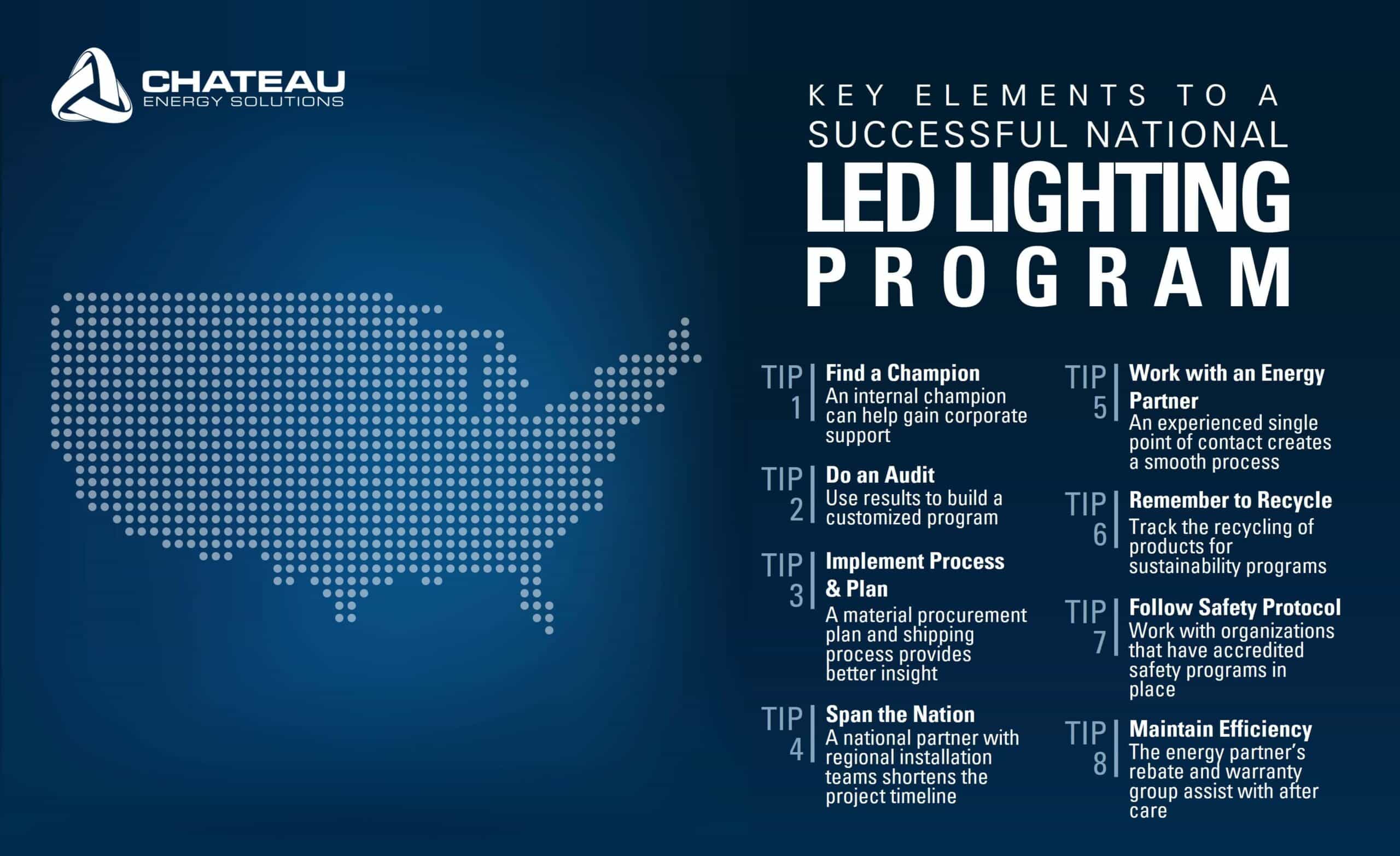

There are several key elements to the successful design and implementation of a national LED lighting program:

1. Find a Champion. It is helpful to have an internal executive champion at the organization needing the lighting upgrade. One who is knowledgeable about the lighting project and who can communicate with the organization’s internal teams to gain complete corporate support for the program and including corporate funding.

Support from the top down is imperative with a national program, whether you are talking tens, hundreds, or thousands of facilities. There are certain driving factors that should be met, such as selected locations that must meet specific financial criteria and lease structure. There are other decision-making factors driving a program like this, but it is important to ensure continuity across the program. LED lighting programs that are corporately funded typically receive little pushback from the facility managers.

2. Do an Audit. Completing a detailed written facilities survey and then performing actual onsite audits are also critical. Just as all good meals start with fresh and correct ingredients, a lighting retrofit program across the country or a large regional program is no different. Use the survey and audit results as your guide to a customized solution. It’s extremely helpful on the front end of a program like this to have a very comprehensive and well-processed audit and design program.

3. Implement an RFP Process and Procurement Plan. A comprehensive, well-planned materials procurement strategy, a thorough RFP process, and a shipping and distribution plan are essential. Depending on the size of the program and the complexity of each facility, whether it be a retail facility group or a manufacturing facility group, it is necessary to have a tried and tested material procurement plan and materials shipping process. Having the potential for 30 to 50 different types of lighting products per location and, let’s say, 250 locations, you can certainly see how this is imperative to a program’s success.

4. Span the Nation. If you are upgrading facilities across the country, working with an operations team with a national footprint is important. Look for an organization with a minimum of ten regional installation areas and multiple installation crews in each area. This is where the rubber meets the road. Working with a seasoned group of project managers and installation contractors covering the service area – whether a regional or a national program – is vital. The teams must have specific training with lighting retrofit-only type programs. It is critical during the installation of a lighting retrofit program that the onsite crews do not disturb the operations of the client. This would defeat the purpose of doing the project in the first place if you’re slowing down your core business. Project managers will schedule installation crews at times that will not affect business operations.

5. Work with an Experienced Energy Partner. It is advantageous to have a seasoned operations and administrative team to handle all day-to-day operations of the national lighting upgrade. This partner becomes your single point of contact, so you don’t have to deal with multiple vendors, which can be frustrating and time-consuming. The back-of-house responsibilities to oversee a national or even a regional lighting retrofit program can be very rigorous. Your energy partner will manage the audit, design, engineers, installation teams, project and construction managers, recycling contractors, accounts payable, warranty and rebate administration, shipping and receiving, and many more tasks that aren’t outwardly seen with a lighting retrofit program. I can’t stress how essential these functions are to ensure a smooth lighting program when multiple facilities, multiple utilities, and multiple resources are brought together in a well-orchestrated process.

6. Remember to Recycle. A comprehensive recycling and trash removal process is especially useful in a national lighting retrofit program. Energy efficiency consulting or sustainability programs often require most of the lamps and lighting ballast materials to be recycled and disposed of properly. Recycling materials from your national lighting retrofit program can be a logistical challenge. Instead, ask your Energy Partner if they work with an accredited recycling company with a track record of success. The recycling company will gather and properly recycle the materials and provide a certificate of recycling.

7. Follow Safety Protocol. Safety is never an option; it is a must. Your energy partner should have safety accreditation from Avetta or a similar organization. Avetta-certified companies go through a rigorous certification process and ongoing certifications every year. An approved safety program and proper program management are imperative – safety first.

8. Maintain Efficiency. Quality customer aftercare, rebate administration, and warranty management are the final pieces in a comprehensive lighting retrofit program. Once the installations are completed, recycling is picked up, and the installation team leaves the last facility, it’s beneficial to have a good rebate and warranty administration team in place. Your energy partner can help with this as well. Taking advantage of rebates and incentives will lower the cost of a project. Your energy partner will also work with each manufacturer to manage the warranties on the products that have been installed. Even though LED has a long life, it has been known to fail. Your energy partner will keep up each manufacturer’s warranty, which can range from a 5 to 10-year period.

Keep this decision-making process strategic but simple. When an organization is looking for a partner to implement a national lighting retrofit, be sure your new energy partner has previous successful referenceable experience. The proper national partner for a project of this nature should have numerous successful large national rollouts for different types of facilities, such as manufacturing, distribution, retail, etc., to ensure they have the abovementioned qualifications.

Another key ingredient is to find an organization with financial transparency. There are several ways to accomplish this. One is a cost, plus a program, which would be the cost of the project plus a reasonable and negotiated margin. Another option is to build an open-book pricing model to encompass all cost aspects of a program like this. This process should include the ability to submit a change order when necessary and also should have a negotiated margin for the program.

When looking for the right energy partner, always do your due diligence and contact several references to learn about your potential partner. Many skip this step only to discover later that their new partner falls short of expectations.

Finally, it’s beneficial to find a comprehensive partner that offers a variety of financial solutions, including off-balance sheet leases, capital leases, operating leases, and a capex solution.

Well, we have covered a lot of ground. What I’d like you to take away from this blog is that it’s important to look at your portfolio of buildings and look for ways to reach your energy and decarbonization goals. Whatever you do, please don’t take the “do nothing” approach. A national lighting retrofit program can be as complicated as you make it. Finding an energy consulting partner with the right qualifications and the right experience can make all the difference in the world.

An overall LED lighting program can yield 20 to 50% return on investment, which is unheard of with other types of energy efficiency projects. A LED lighting upgrade should be the first step of an energy optimization and sustainability program but sometimes gets overlooked for more exciting projects like solar installation.

Energy efficiency upgrades often pay for themselves, but your national LED lighting program will have several financing options. All this being said, I hope this information has been helpful in how to start a national LED lighting retrofit program. I wish you great success as you move forward with your efficiency and sustainability efforts.

The Chateau Energy team has more than 30 years of lighting design and installation expertise. Learn more about our lighting upgrade and retrofit solutions and the customers we’ve helped. We’d love to help you too.

Jim Dore is the Vice President of Service Solutions and leads the business development team at Chateau Energy Solutions. He has 25 years of experience in consulting, designing, selling, and funding energy efficiency and electric vehicle infrastructure projects and programs. Jim has been directly involved with more than $125 million in energy-efficient turn-key projects throughout his career. His experience, deep industry knowledge, and relationships keep Jim at the forefront of emerging energy technology and program funding solutions. Contact Jim on LinkedIn.

Chateau Energy Solutions Making Energy an Asset®

Ready to get started on the path to energy efficiency and sustainability?